In the world of industrial packaging, securing materials efficiently is paramount. Whether you’re running a warehouse, handling mass shipments, or working in a manufacturing facility, the tools you use to package your products can make a significant difference in your operations. One such essential tool is the industrial stapler. Often overlooked, this powerful device is a key player in ensuring that packaging is both secure and durable.

In this blog, we’ll explore the world of industrial staplers, delving into their benefits, applications, and why they are a must-have for any business engaged in heavy-duty packaging operations. Following Google’s E-E-A-T guidelines (Experience, Expertise, Authoritativeness, and Trustworthiness), we aim to provide you with well-researched, human-generated, and factually accurate information.

What is an Industrial Stapler?

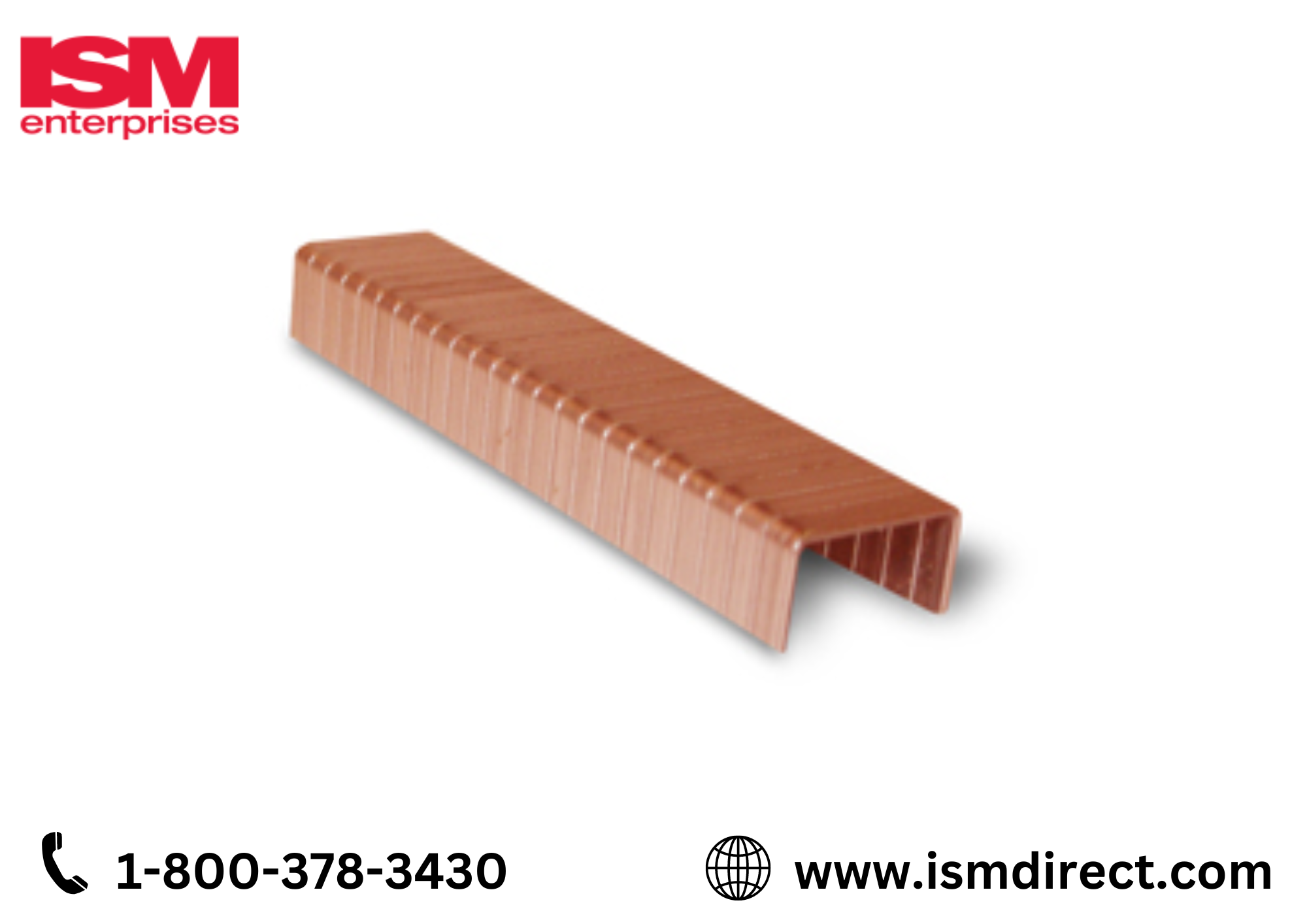

An industrial stapler is a heavy-duty tool designed to handle tough materials such as cardboard, corrugated boxes, and large batches of paper. Unlike your typical office stapler, industrial staplers are built to secure thick layers of material with minimal effort and maximum durability. They come in various types and sizes, depending on the materials you need to fasten and the volume of packaging involved.

There are manual, pneumatic (air-powered), and electric models available, each suited for different applications. These staplers are commonly used in industries like packaging, construction, furniture making, and manufacturing, where reliable and sturdy fastening is critical.

The Importance of Industrial Staplers in Packaging

- Durability and Strength

One of the primary reasons businesses rely on industrial staplers is the strength they provide. Industrial packaging often involves sealing heavy or bulky materials that require more than just tape to stay intact. Staples offer a secure seal that can withstand rough handling during transportation, ensuring that packages remain closed throughout their journey.

When compared to alternatives like adhesives or regular tapes, staples offer a longer-lasting and more dependable solution, especially in environments where the packages are exposed to stress or humidity. This durability minimizes the risk of product damage and helps maintain the integrity of the packaging.

- Efficiency and Speed

Time is money, especially in industries with high-volume production lines. Industrial types of Packaging Staplers are designed to streamline the packaging process by providing a fast and efficient way to seal boxes. With just a single action, a stapler can secure a box, which is much faster than manually applying tape or other sealing methods.

This increase in efficiency is particularly important for businesses that handle large volumes of packaging daily. Faster packaging leads to improved productivity and helps businesses meet their shipping deadlines without compromising on quality.

- Cost-Effective Solution

Though the upfront cost of industrial staplers may seem higher than alternatives like tape dispensers, they offer a more cost-effective solution in the long term. Staples are cheaper than tape, and one strip of staples can seal multiple boxes before needing to be replaced. Furthermore, fewer materials are required, and there is less chance of packaging failure, which reduces the cost of returns or damage claims.

For businesses seeking a reliable, affordable packaging solution, investing in an industrial stapler can lead to significant savings over time.

- Versatility

Industrial staplers aren’t limited to just packaging. Their versatility extends to various industries where strong, reliable fastening is required. They are frequently used in:

- Construction: To fasten materials like insulation or sheathing.

- Furniture making: For securing upholstery to wooden frames.

- Agriculture: To seal sacks or bundle crops.

- Printing and bookbinding: For binding large volumes of paper.

This versatility makes industrial staplers an invaluable tool in a wide range of industries beyond just packaging.

- Eco-Friendly Option

In an age where sustainability is a priority for businesses and consumers alike, industrial staplers offer an eco-friendly alternative to traditional packaging methods. Staples are made of recyclable metal and do not contribute to plastic waste, unlike tape, which often contains non-recyclable materials.

Using staplers for packaging can help reduce your business’s carbon footprint, aligning your operations with eco-conscious practices and appealing to environmentally aware consumers.

Choosing the Right Industrial Stapler

When it comes to choosing the best industrial stapler for your business, several factors should be considered:

- Manual, Pneumatic, or Electric?

The type of stapler you choose largely depends on your volume of packaging and your operational setup.

- Manual staplers: Ideal for smaller operations or where portability is needed. They are lightweight, require no additional power source, and are great for moderate packaging tasks.

- Pneumatic staplers: These are air-powered and are the best choice for high-volume operations. They offer consistent power, reducing the strain on operators and speeding up the packaging process.

- Electric staplers: These staplers are powered by electricity and are suited for industrial settings where constant, fast stapling is required. They provide more power than manual models and are easier to operate for extended periods.

- Box Size and Material

The thickness and type of material you’re working with will determine the kind of stapler and staples you need. Thicker materials require longer staples with more penetration power, while thinner materials can be secured with shorter staples. Make sure the stapler you choose can accommodate the size and type of boxes or materials you’re working with.

- Durability and Build Quality

Industrial staplers are built to last, but it’s essential to choose a model that is known for its durability and reliability. Look for models made from high-quality materials like steel, which can withstand the rigors of daily use in an industrial environment. A well-built stapler will require less maintenance and have a longer lifespan, saving you both time and money in the long run.

- User Comfort

If your employees are going to be using staplers frequently, ergonomics matter. A stapler that is easy to handle and minimizes strain on the operator will increase productivity and reduce the risk of injury. Look for features like comfortable grips, lightweight designs, and easy trigger mechanisms.

Why ISM Direct is Your Best Choice for Industrial Staplers

When it comes to finding reliable and high-quality industrial staplers, ISM Direct is a leading provider. With years of experience in the industry, ISM Direct specializes in offering a wide range of packaging solutions, including carton closing tools, staples, and heavy-duty industrial staplers.

Here’s why ISM Direct is the go-to choice for businesses looking to optimize their packaging operations:

- Top-Notch Quality

ISM Direct prides itself on providing durable and reliable products. Their industrial staplers are made from high-grade materials that are designed to handle the demands of busy packaging environments. Whether you need manual, pneumatic, or electric models, their tools are built to last and perform consistently.

- Wide Product Range

No matter what your packaging needs are, ISM Direct has a solution for you. Their selection of industrial staplers includes models for every application, from small-scale operations to large industrial setups. In addition, ISM Direct provides the staples and other accessories you’ll need to ensure your packaging process runs smoothly.

- Expert Support

With ISM Direct, you’re not just buying a product; you’re gaining access to a team of experts who understand the intricacies of packaging. Their knowledgeable staff can help you choose the right industrial stapler for your needs and provide advice on maintaining and using the equipment effectively.

- Competitive Pricing

ISM Direct offers high-quality packaging solutions at competitive prices, ensuring that businesses of all sizes can afford the tools they need to succeed. By offering cost-effective industrial staplers and staples, ISM Direct helps businesses improve their operations without breaking the bank.

Conclusion

An industrial stapler is an essential tool for businesses that rely on secure, efficient, and cost-effective packaging. Whether you’re sealing boxes for shipping, fastening construction materials, or working in a high-volume production line, an industrial stapler can significantly improve your operations.

By choosing a durable and reliable stapler, businesses can enjoy increased productivity, reduced packaging costs, and greater peace of mind knowing that their products are securely sealed. For businesses in need of high-quality industrial staplers, ISM Direct is the trusted source for reliable and affordable packaging solutions.

Invest in an industrial stapler today and take the first step toward streamlining your packaging process, boosting efficiency, and ensuring your products are safe during transit.